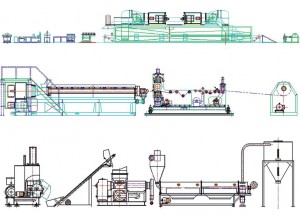

XLPE Foam Sheet Extrusion Line

» Features of the machine

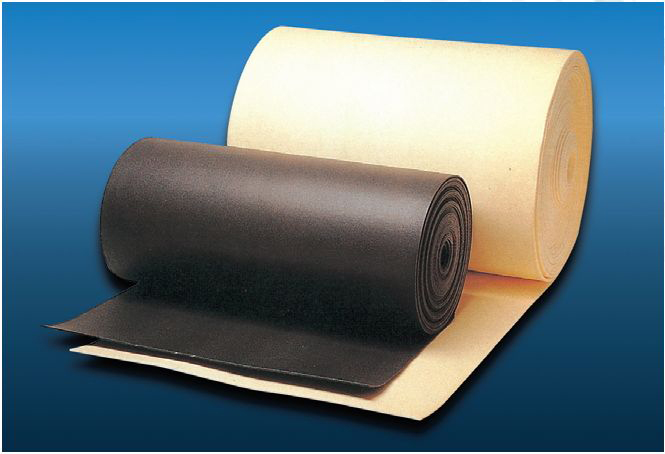

Pacific Industry Co., Ltd, as a global leader of PE foam extruders, provides the world best Crosslinked PE Foam Sheet Production Line to produce chemically crosslinked closed cell polyethylene foam sheet in continuous rolls with smooth, uniform, and aesthetic surface. This line is manufacturing the most preferred insulation material with the most advanced and innovative technologies. Our XPE foam machine are installed in India, USA, Russia, Saudi Arabia, Vietnam, Malaysia, Indonesia, Philippines, etc.

» Characteristics of XLPE foam

∙ Superior cushioning

∙ Great heat-insulating power

∙ High buoyancy

∙ Little water absorption

∙ Outstanding weather stability and chemical resistance

∙ Soft, strong with beauty

∙ Easy to fabricate

∙ High thermal stability

» Specification

| Model No. | PI-XPE-150 | PI-XPE-170 |

| Capactiy | Max. 150kg/hr | Max. 250kg/hr |

| Sheet width | Max. 1600mm | Max. 2400mm |

| Sheet thickness | Max. 15mm | Max. 15mm |

| Density | 25~200kg/m3 | 25-200kg/m3 |

| Electricity | 350kw | 500kw |

» Applications

∙ Automobile, marine, and aerospace vehicles

∙ Building/construction thermal insulation, and moisture resistance

∙ All kinds of single or double coated tape product

∙ Camping mats and hockey helmets

∙ Healthcare appliance type products

XLPE Foam Sheet Extrusion Line FAQ

1. What is application of XLPE foam??

2. What is the manufacturing process of XLPE foam?

3. Which kinds of converting is available by XLPE foam?

4. What is difference of XPE foam machine from Pacific Industry Co., Ltd. compared with other global PE foam manufacturers?

– Even foaming/expansion to minimize material loss

– Less than 2% total loss/wastage

– Regular thickness and uniform cell structure with high crosslinking ratio (48%)

– Capability to produce thick (up to 15mm) and extra-wide (up to 2600mm) XPE foam

– Excellent flame retardant (FR) performance

5. What is guarantee of XPE foam machine from Pacific Industry Co., Ltd. compared with other global PE foam manufacturers?

– Installation and two test runs (one before shipment at our factory and one after installation at buyer’s factory)

– Technical transfer during test runs

*During installation and test-run periods, round-trip air tickets and accommodation for dispatched engineers will be at the buyer’s expense.*