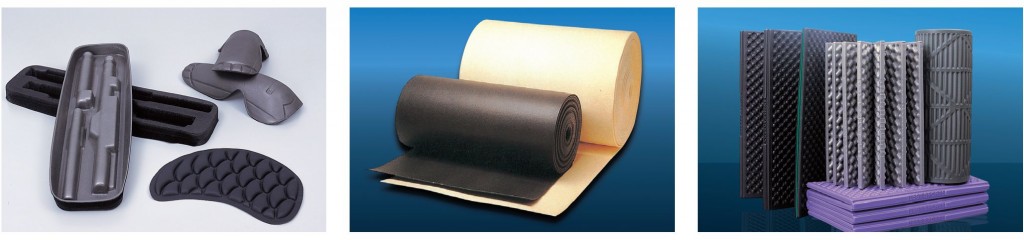

XLPE, XPE Foam Sheet

Features

XLPE is chemically crosslinked PE foam. It is produced in continuous rolls resulting in a foam product with uniform, closed cells and smooth skins on both sides. It is light weight, flexible and soft to touch, yet strong, tough, resilient and resistant to moisture, many chemicals and temperature extremes.

Compared with non-crosslinked polyethylene foam, it typically offers superior thermal stability and insulating properties plus improved dimensional consistency and stability over a wide range of fabrication methods and end-user’s conditions.

XLPE foams are used as insulation and sound absorbing materials in a host of container’s designs.

It is easy to work in fabricating and thermoforming. XLPE foams are right at home in the building and construction industry where thermal insulation, moisture resistance, sound and vibration are critical. Indoor or outdoor XLPE foams build success.

XLPE foams also used in backpack padding, luggage and similar application are benefiting from a wide array of beautiful colors and variable densities.

Characteristics

- Superior cushioning

- Great heat-insulating power

- High buoyancy

- Little water absorption

- Outstanding weather stability

- Chemical resistance

- High resistance to wear and tear

- Soft, strong and beautiful

- Easy fabrication

- VOC-free at 80°C (Heat resistant at 110°C)

Specifications

| Units | Specifications | Remarks |

| Density | 20kg-170kg/m3 | |

| Thickness | 3mm-15mm | direct goods |

| Thickness | 1mm-2mm | sliced goods |

| Thickness | 12mm~ | bonded goods |

| Width | 800mm-2400mm | |

| Length | can be controlled |

Properties

| Items | X1000 | X1500 | X1700 | X3000 | X4000 | |

| Expansion ratio(times) | 10 | 15 | 20 | 30 | 40 | |

| Specific gravity(Density) | 0.1 | 0.067 | 0.05 | 0.033 | 0.025 | |

| Tensile strength(㎏/㎠) | Lengthwise | 9.5 | 7 | 4.8 | 3.0 | 2.5 |

| Widthwise | 8.2 | 6.2 | 4.0 | 2.4 | 2 | |

| Elongation(%) | Lengthwise | 180 | 160 | 140 | 110 | 100 |

| Widthwise | 190 | 170 | 150 | 120 | 110 | |

| Tear strength(㎏/㎝) | Lengthwise | 6.0 | 4.1 | 2.8 | 1.8 | 1.5 |

| Widthwise | 6.5 | 4.3 | 3.1 | 2.0 | 1.8 | |

| Compression strength(㎏/㎠) | 1.3 | 0.94 | 0.58 | 0.42 | 0.35 | |

| Compression set(%) | 3.5 | 4 | 5.1 | 6.6 | 7.5 | |

| Repeating compression set(%) | 4.9 | 6.2 | 7.5 | 9.1 | 9.8 | |

| Creep weight(㎏/㎠) | 0.5 | 0.25 | 0.1 | 0.05 | 0.03 | |

| Resiliency(%) | 36 | 39 | 42 | 47 | 51 | |

| Thermal conductivity(kcal/mh℃) | 0.041 | 0.040 | 0.038 | 0.036 | 0.035 | |

| Shrinkage at 70C(%) | Lengthwise | -0.7 | -1 | -1.3 | -1.7 | -2.5 |

| Widthwise | -0.2 | -2.5 | -0.3 | -0.5 | -0.6 | |

| Water absorption(㎎/㎠) | 0.06 | 0.08 | 0.1 | 0.19 | 0.21 | |

| Heat resistant temperature | +80C | +80C | +80C | +80C | +80C | |

| -100C | -100C | -100C | -100C | -100C | ||

Applications

- insulation steel sheets

- construction duct

- signal pads

- sound proofing materials

- gaskets

- toilet cover

- insulation for train

- automobile

- pads in backpack

- car steering cover

- inside sports recreational goods

- marine and aerospace(vehicles)

- insulation pipe cover

- outdoor mattress

- cases